The purpose of this procedure is to provide general guidelines for implementation of controls to reduce the risk of contaminating the workplace and the natural environment. This standards safety instruction applies to all project site workplaces for maintaining good house keeping. Building

Read More

This risk assessment is applicable for Chop Saws, Angle Grinders, Bench Grinders, cutting and grinding tasks in mechanical, fabrication and electrical disciplines. Hazards related to abrasive wheel include: Fire/explosion through ignition of sparks Bursting of abrasive wheel or disc at high speed Contact with wheel or

Read More

This electrical risk assessment covers all operations related to electrical LV, MV inspection and testing. Related hazards include: Electrocution Electric Burn Fire Explosion Control Measures 5 Golden Rules to avoid accidents due to electricity: 1. Disconnect completely ( the apparatus on which

Read More

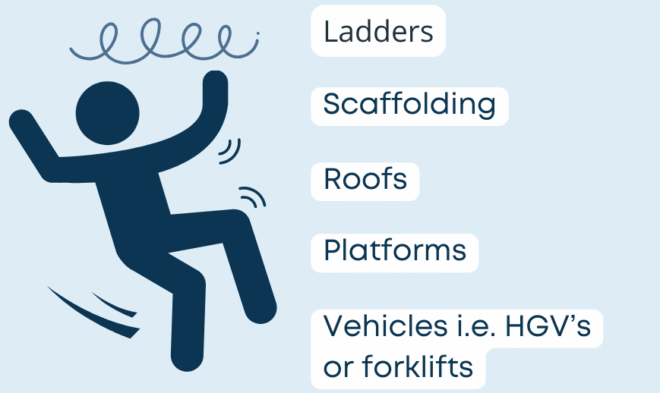

Below is work at height risk assessment that covers work in any place including at or below ground level and/or obtaining access to a place of work where an employee could fall a distance liable to cause injury. Scope of work may

Read More

This risk assessment is applicable for all persons involved in transporting or supporting of a load by 1 or more employees and includes lifting, putting down, pulling, pushing, carrying or moving a load, which, by reason of its characteristics or of unfavorable

Read More

This risk assessment is applicable for all kind of operations including the use of tools and equipment’s. Scope of the document is all locations including sites, offices, stores, workshops, canteens, dry rooms, toilets etc. For all type of work activities at the same

Read More