Activity: Use of electrical equipment’s

Hazards & Risks: Electrical Shock, Cables management issues, Personal Injury

Control Measures:

– Fire exit routes / Muster points shall be properly indicated by installation of signs.

– Working areas shall be barricaded (only authorized personnel are allowed to enter).

-Electrical Hand tools will be inspected before start the job by the Supervisor.

-All cables will be inspected by the competent person.

-All crew shall wear steel toe safety shoes, eye protection, gloves, hard hat and coverall and safety vest jackets.

-Cable management shall be arrange on daily basis.

-Fire extinguisher shall be available near to electrical equipment.

-Emergency contact list shall be displayed on site.

Activity: House keeping

Hazards & Risks: Excess and egress issues, Personnel injury

Control Measures:

-Proper housekeeping shall be on daily basis.

-Access and egress will be clear for emergency purpose.

Activity: Transportation of material on site Loading / offloading of material manually and using Trailer, Forklift

Hazards & Risks:

– Improper loading of material

– Falling Object / material hazard

– Fire hazard

– Struck against (Fork lifter)

– Personnel Injury due to slip / trip, struck against, struck by and fall from height

– Road Traffic Accidents

– Material fall during transportation

– Roll down of material

– Damage of material during shifting

– Environmental Hazard due to leakage of oil from equipment

– Back pain

– Muscular skeletal disease,

– Pinch points.

– Hand injury

Control Measures:

– STARRT will be conducted by Supervisor.

– Supervisor will be responsible to complete safe activity pre-checklist sheet daily before start of work.

– Loading of material will be done under proper supervision.

– Ensure that overloading is prevented

– Secure all material properly

– Banks man will l wear high visibility Vest for identification.

– Barricade the loading / offloading area.

– License holder operator will operate the fork lifter/ JCB.

– Double Tag line to be used to control load during lifting.

– Banks man with vest to guide all vehicle maneuvering.

– Highlight any protruding load.

– Use proper signboards

– Fork lifter and crane to be used as per size, shape and weight of load

– Safe access to be provided in case of requirement.

– No un-authorized person allowed in the area.

Activity: Working in night/dark

Hazards & Risks:

-Personnel injury

-Electrical shock

-Poor lighting

Control Measures:

– STARRT to be implemented and monitored. Tool Box Talk on weekly basis conducted by Site Management.

-Proper lighting shall be on site for night shift activities.

– Housekeeping shall be on daily basis.

STARRT will be conducted to peoples about the night work hazards.

-Access and aggress should be clear.

Activity: Working in Hot Conditions

Hazards & Risks: Heat Stress

Control Measures:

– STARRT to be implemented and monitored.

-Drinking water will be available for peoples on site.

-STARRT meeting special focus on Heat stress prevention.

– Rest hours shall be according to the local rules and regulation.

Activity: USE Of Equipment Compressor, Cutting machine, Floating machine

Hazards & Risks:

– Risks due to defective Plant / equipment.

– Working in Dark/ Night Hours

-Electrical Shock

– Personal injury

Control Measures:

– Defective cables should not be in use.

– Working areas shall be barricaded (only authorized personnel are allowed to enter).

– All crew in charge should wear safety shoes, Eye protection, gloves, hard hat and coveralls.

– Hand tools should be inspected before start the job by the Supervisor.

– Damaged tools tagged out & removed from site immediately.

– Mixer machine machine must be guarded and personal must be trained for the operation of mixer machine.

– All cables will be inspected by the competent person Damaged electrical cords to be repaired and taken out of service immediately.

– Compressor hoses need to be secure using a whip check to prevent accident ally disconnect of hoses.

– Cutting machine must be guarded and personal must be trained for the use of the machine.

– Mandatory PPE must be use all personal on site, for different task Cutting job Face protective shield, ear plugs, Mixer job ear plugs and dust mask, for concrete work steel toe robber safety shoes, rubber gloves, for floating roller ear plug, mask, and gloves for the tasks.

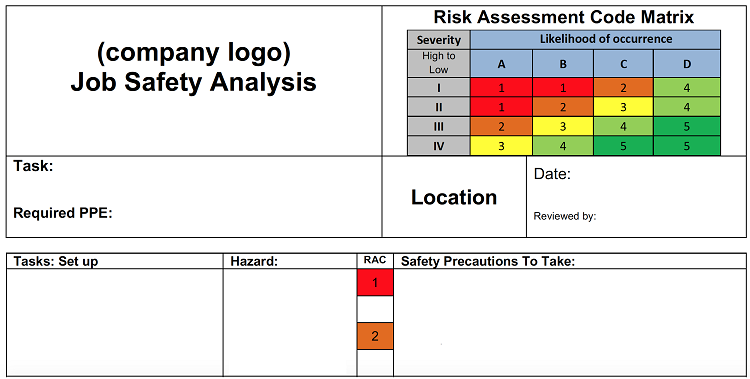

You can download job safety analysis template from below link:

Sample job safety and environmental analysis format template

Discover more from Project Management 123

Subscribe to get the latest posts sent to your email.