This procedure defines the requirements for gabion wall basket or mattress installation works, in order to maintain the soil stability for any kind of installations including landscaping and pipe works etc.

Where multiple activities are scheduled, the general contractor is to review in advance the priority of work and schedule the appropriate time frame to allow each to complete their scope of work.

Prior to any work commencing supervisors must conduct a hazard assessment of all applicable work areas.

Any hazards that are found during the hazard assessment must be addressed prior to start of any civil work.

Arrange following tools and materials before starting the wire basket installation works:

- Welding machine

- Wire galvanized assemblies

- Wire ties and connectors

- Gravel

- Standard Safety Equipment (gloves, goggles, safety helmet, etc.)

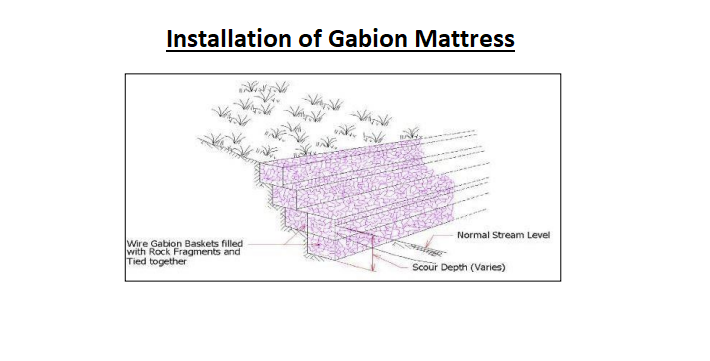

Foundation Preparation for Gabion Wall Installation

The foundation on which the gabions are to be placed shall be cut or filled and graded to the lines and grades shown on the drawings.

Surface irregularities, loose material, vegetation, and all foreign matter shall be removed from foundation surface area.

When fill is required, it shall consist of materials conforming to the specified requirements.

Gabion basket and bedding or specified geotextiles shall not be placed until the foundation preparation is completed, and the subgrade surfaces have been inspected and approved by the engineer or the engineer’s representative.

Compaction of bedding or filter material will be required per plans and specifications.

The surface of the finished material shall be to grade and free of mounds.

Extra care should be taken with foundation preparations in order to ensure a level and smooth surface.

Geotextile shall be installed in accordance with the requirements of the plans and specifications.

Gabions Placement Procedure

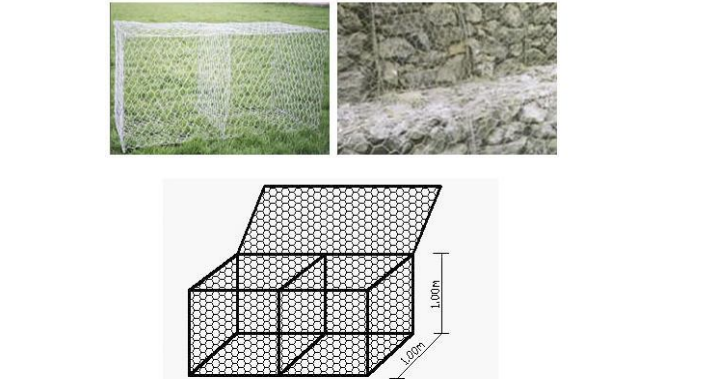

Place the empty gabions on the foundation and interconnect the adjacent gabions along the top, bottom, and vertical edges using lacing wire or spirals.

Wrap the wire with alternating single and double half hitches at intervals between 100 mm and 150 mm.

Spiral fasteners are commonly used for the assembly and interconnection of welded mesh gabions.

Spirals are screwed down at the connecting edges then each end of the spiral is crimped to secure it in place.

Lacing may be used as needed to supplement the interconnection of welded mesh gabions, and the closing of lids.

Interconnect each layer of gabions to the underlying layer of gabions along the front, back, and sides.

Stagger the vertical joints between the gabions of adjacent rows and layers by at least one-half of a cell length.

Filling of Gabion Baskets

After adjacent empty wire gabion units are set to line and grade and common sides properly connected, they shall be placed in straight-line tension to gain a uniform alignment.

Staking of the gabions may be done to maintain the established proper alignment prior to the placement of rock.

Connecting lacing wire and other fasteners (as allowed) shall be attached during the filling operation to preserve the strength and shape of the structure.

Internal connecting cross-tile wires shall be placed in each unrestrained gabion cell greater than 500mm in height, including gabion cells left temporarily unrestrained.

Two internal connecting wires shall be placed concurrently with rock placement, at each 300 mm interval of depth.

In welded mesh gabions these crossties or stiffeners will be placed across the corners of the gabions (at 300 mm from the corners) providing diagonal bracing.

Lacing wire or preformed wire stiffeners may be used.

The gabions shall be carefully filled with rock, either hand methods, ensuring alignment, avoiding bulges, and providing a compact mass that minimizes voids.

Geotextile Installation Method

Unsuitable soil must be cleared from the site and the foundation soil shall be excavated or filled and leveled to the designer’s requirements.

Sharp objects i.e. stumps, boulders or construction material that can puncture the geotextile shall be removed from the site.

Use the approved geotextile only.

Geotextile shall be manually unrolled over the soft soil.

Care should be taken during unrolling to avoid wrinkles and to prevent damage to the geotextile.

Make connection of geotextile overlapping each sheet mounted on the next sheet.

In the curved mounting area (e.g. street corner), geotextile installation shall follow the direction of the curve.

If the geotextile is installed to direct sunlight then use black geotextile.

Discover more from Project Management 123

Subscribe to get the latest posts sent to your email.