Purpose

This method of statement covers the installation of conduits – Cast in situ, Concealed on Block Walls, Surface mounted and Underground Installations as defined in the project general specification.

Scope of Works

This procedure will define the method to be used to ensure that conduit installations and workmanship are correct and acceptable and shall conform to the Contract Documents and Specification.

Responsible Personnel on Site

- Construction Manager

- Electrical Field Engineers

- Safety Officer

- QA/QC Engineer

- Electrical Supervisors

Storage

- Conduits shall be properly supported and stacked on a flat surface.

- Conduits shall be protected from sunlight and moisture by covering them with tarpaulin.

- Conduit fittings shall be stacked properly in neat and orderly manner.

Pre-Installation

- All materials and documentation relevant to this particular Section of works will be checked by the Construction Department prior to the commencement of works. Ensure that all materials to be installed are inspected and accepted by the Consultant.

- Access to start the work will be confirmed that they are in a suitable condition for permanent works to commence.

Conduit Installation Procedure

Conduit Installation – Cast in situ

- Measure and mark-up shuttering for the position of the boxes.

- Fix the boxes on their designated locations. Ensure that the Boxes are filled with polystyrene to prevent cement sediment to accumulate inside the boxes.

- First layer of reinforcing bar to be installed.

- Installed in situ conduits as per requirements, tie the conduits into the reinforcing bars. Ensure that the maximum run of conduits between two boxes shall not contain more than three (3) quarter bends. Ensure that the maximum run of conduit between boxes shall not exceed 25m for straight runs. In any cases that the straight run of conduit will exceed 25m, pull boxes shall be installed.

- Wherever necessary, nylon rope shall be pulled into the conduit run for future purposes. Leave a slack of 300mm minimum at each end of conduit.

- After installation of conduits, the second layer of reinforcing bar installation will proceed. Ensure that all installed conduit shall be taken care off.

- Raise Request for Inspection of Conduit Installation.

- Shutter closing and concreting will commence.

Embedded Conduits on Walls

- Mark the position of boxes and conduits on the walls.

- Chase the wall using appropriate tools i.e., electric concrete cutter and chisel.

- Fix the boxes on their final position. Make sure that the boxes are properly protected with polystyrene to prevent entry of foreign materials.

- Install embedded conduits.

- Raise Request for Inspection of Conduit Installation.

- After the works has been inspected, plastering of walls will commence.

Surface Mounted Conduit Installation

- Establish the conduit route and mark using chalk liner on ceiling or walls.

- Mark the position of the boxes.

- Install the boxes on their proper location.

- Install saddle clamp base. For non-metallic conduits, spacing between saddle clamps will not exceed 1m, and for metallic conduit, spacing between saddle clamps will not exceed 1.5m.

- Install the conduit runs. Make sure that the conduit runs will not contain three (3) quarter bend.

- Where in the conduit runs will cross expansion joint, expansion coupling will be used.

- Ensure that the spacing between parallel runs of conduit is uniform throughout the installation.

- Raise Request for Inspection of Conduit Installation.

Underground Duct Installation

- Mark the route of the underground duct.

- Excavate the underground duct route until the required depth.

- Check the depth of the trench for proper elevation. Ensure that the trench is free from debris and foreign materials.

- Install the PVC duct.

- Raise Request for Inspection of PVC duct Installation.

- After inspection is carried out and the said works has been signed-off by the Consultant, back fill the trench with approved back-fill material.

- Install Warning Tapes 300mm below the finish grade.

- Raise Request for Inspection for Warning Tape Installation.

- after inspection is carried out and the works has been signed-off, back fill the trench until the finish grade. Ensure that the back fill material is properly compacted.

Reference Documents

Approved Electrical Shop Drawings

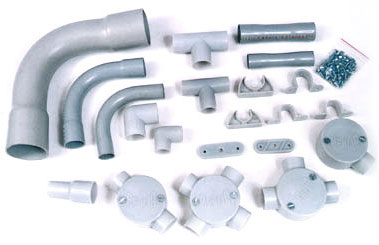

Approved Material Submittals for Conduits and Boxes

Approved Material Inspection Report

Approved Safety Plan

Approved QA/QC Inspection Plan.

Safety

- All safety precautions shall be followed as per approved safety plan & procedure. Ensure all involved persons are aware of the same.

- Tradesman shall ensure that before leaving their working places, it must be clean, tidy and free from rubbish.

Discover more from Project Management 123

Subscribe to get the latest posts sent to your email.