The purpose of this procedure is to determine the specific gravity and water absorption of given sample of aggregates for road works.

Specific gravity of an aggregate is considered to be a measure of strength or quality of the material.

Stones having low specific gravity are generally weaker than those with higher specific gravity values.

The specific gravity test helps in the identification & classification of stone.

Water absorption gives an idea of strength of rock stones having more water absorption are more porous in nature and are generally considered unsuitable unless they are found to be acceptable based on strength, impact and hardness.

Desirable values of Aggregate Specific Gravity

The specific gravity of aggregates normally used in road construction ranges from about 2.5 to 3.0 with an average value of about 2.68.

Although high specific gravity of an aggregate is considered as an indication of high strength, it is not possible to judge the suitability of a sample of road aggregate without finding the mechanical properties such as aggregate crushing, impact and abrasion values.

Water absorption of an aggregate is accepted as measure of its porosity.

Sometimes this value is even considered as a measure of its resistance to frost action.

Water absorption value ranges from 0.1 to about 2.0 percent for aggregate normally used in road surfacing.

Stones with water absorption up to 4.0 percent have been used in base courses.

Generally a value of less than 0.6 percent is considered desirable for surface course, though slightly higher values are allowed in bituminous constructions.

Some standards specify the maximum water absorption value as 1.0 percent for aggregates used in bituminous surface dressing and built-up spray grout.

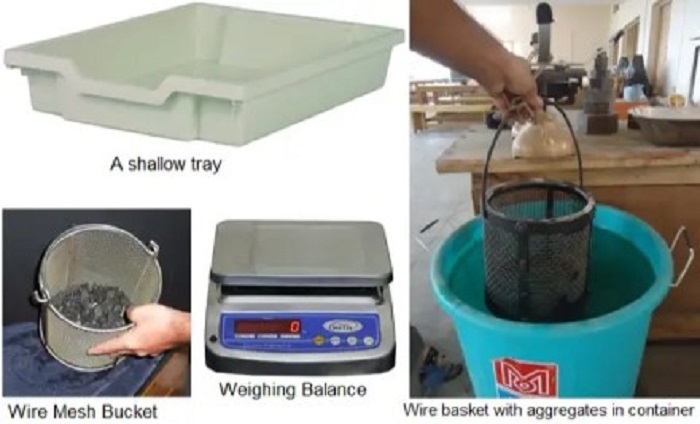

Apparatus & Tools Required

a) Density basket

b) Weighing balance

c) Water tank

d) Tray

e) Sieves- 10mm and 20mm

Test Procedure

Take about 2kg of given aggregates passing 20mm sieve and retained on 10mm sieve.

Keep the aggregate in density basket and then keep the basket in water.

Allow the aggregate and basket to be in water for 24 hours.

After 24 hours find the suspended weight of basket with aggregate.

Remove the basket out of water and remove the aggregate.

Keep the empty basket back in water and find the suspended weight.

Wipe the surface of aggregate using a cotton cloth to make them surface dry.

Find the weight of surface dry aggregate in air.

Keep the aggregate in oven at 110° C for 24 hours.

Now find the weight of dried aggregate in air.

Then specific gravity and Water absorption is calculated from the relation as below table.

| Weight of saturated aggregate suspended in water + basket ‘W1’gm | |

| Weight of empty basket in water ‘W2’ gm | |

| Weight of saturated aggregate in water ‘Ws’ = (W1-W2) gm | |

| Weight of surface dry aggregate ‘W3’ gm | |

| Weight of equal volume of water to the aggregate = W3-Ws gm | |

| Weight of oven dry aggregate ‘W4’ gm | |

| Specific gravity = W4 / [W3-(W1-W2)] | |

| Water absorption = W3-W4 * 100 % W4 |

Discover more from Project Management 123

Subscribe to get the latest posts sent to your email.